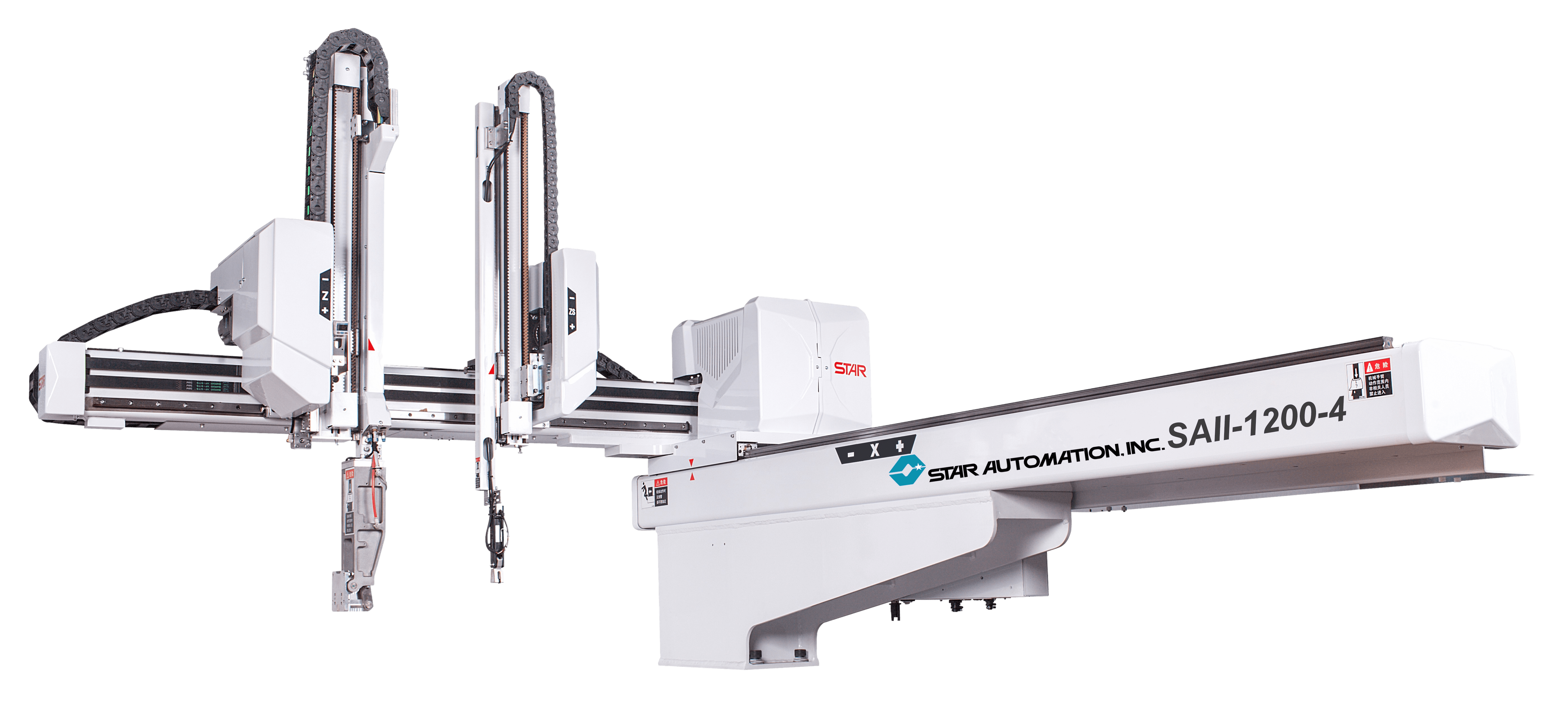

SAII-1200-4 Injection Molding Servo Robots

SAII-1200-4

| Vertical Stroke (mm) |

Range of IMM (Ton): |

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

Download Model PDF |

|---|---|---|---|---|

| 1200 | 350-600 | 2000 | 1180 |

|

Technical Specs:

The SA-4 is comprised of a variety of servo motor driven automatic unloaders, each built to increase the efficiency and quality of your factory’s automation. The SA11-1200-4 is manufactured with a touch screen, multicolor operation keys, and two-language exchange (English and Spanish) for ease of use. THK linear motion rails exist on all axis to minimize vibration and improve stability. Enjoy energy cost savings with 25%-reduced power consumption and 75%-reduced air consumption.

Star Automation’s SAII Series servo motor driven automatic unloaders are manufactured to increase the efficiency and quality of your factory’s automation. Equipped with easy to operate, high-performance pendants the SAII Series servo robots can be operated by anyone once properly trained. Star Automation will help you find the model best suited for you, then provide industry-best customer service and maintenance beyond the sale. We'll even provide implementation and operator training.

View product PDF for full specifications and diagrams.

|

Power Source |

200 VAC ± 10% 60 Hz |

|

Air Pressure |

70 psi (.48 MPa) |

|

Drive System |

AC SERVO MOTOR |

|

Posture (air cylinder) |

90° |

|

Max. Load, Incl. Chuck Weight |

22 lbs (10 kg) |

|

Posture Torque |

43.52 ft-lbs |

|

Control Types |

Options Functions

- Additional Vacuum Generator with Part Present Sensor

- Additional Part Grip

- Nipper on Chuck

- Rotation 90°, 180° 2-Position, 180° 3-Position

- Shuttle on Tool

- Mold Spray

- Air Blow

- 1-3 Color Alarm Light

- Special Paint

- Central Lube

- Central Lube

- Expansion I/O 16 in/out

- Quick Chuck Change

Overall Dimensions

|

|

SAII-1200-4 |

SAII-1200S-4 |

|

Overall Height |

61.06” (1551mm) |

61.06” (1551mm) |

|

Overall Width |

113.62” (2886mm) |

113.62” (2886mm) |

|

Traverse Stroke |

78.74" (2000mm) |

78.74" (2000mm) |

|

Overhang, release side |

12.32” (313mm) |

12.32” (313mm) |

|

Cable Guide Overhang |

2.32” (59mm) |

2.32” (59mm) |

|

(P) Vertical Stroke |

47.24" (1200mm) |

47.24" (1200mm) |

|

(P) Vertical Standby |

7.72” (196mm) |

7.72” (196mm) |

|

Bottom of Crosswise to Chuck Mount Position |

13.94” (354mm) |

13.94” (354mm) |

|

Crosswise arm |

69.80” (1773mm) |

69.80” (1773mm) |

|

(R) Vertical Standby |

- |

9.69” (246mm) |

|

(P) Crosswise Reach Max |

49.92” (1268mm) |

49.92" (1268mm) |

|

(P) Crosswise Stroke Max |

46.46" (1180mm) |

39.76" (1010mm) |

|

(P) Crosswise Standby Min |

3.46" (88mm) |

10.16" (258mm) |

|

(P) (R) Proximity Min |

- |

7.52” (191mm) |

|

(R) Crosswise Stroke Max |

- |

39.76" (1010mm) |

|

(R) Crosswise Standby Min |

- |

2.64” (67mm) |

|

Base Offset |

2.75” (70mm) |

2.75” (70mm) |

|

Mold Mounting Face - Box End |

17.95” (456mm) |

17.95” (456mm) |

Standard Functions

- Vacuum Generator with Part Present Sensor

- Part Grip Circuit

- Sprue Grip Circuit

- Free Packaging

- Sample and Chuck Change Positions

- Product Packaging (256 each axis)

- CNC Step Programming

- SD Memory Card

- CPC® and AMP® Connections at the Head

- Active Vibration Control

- IMM Mounting Weldment

- Multi-Level Password Protection

- Position, Speed and Timer Adjust in Auto

- Alarm History

- LM Bearings w/ Zerk Fittings