Arburg IMMs are known around the world for their precision and durability. Automation robots and tooling from Star Automation further boost Arburg systems' performances.

By using a standardized 32-pin and 50-pin robot to press interface, Arburg injection molding systems are compatible with Star Automation machines. Legacy presses use direct wiring through a terminal strip interface to achieve compatibility.

Get training to properly operate the new system. Even after training is done, Star Automation remains available to answer any questions or provide further training, maintenance, and repair.

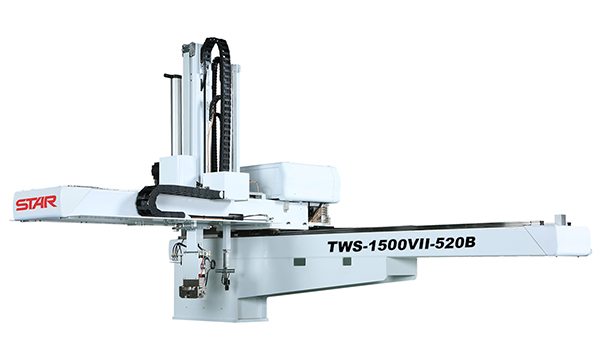

Servo Robots for Arburg Injection Molding Systems

As a major supplier of servo motor-driven take-out machines for Arburg, automatic unloaders from Star Automation are always intuitive for the operator to use. Little training is required. Arburg IMMs with injection ranges between 20-4 and 2500-5000 tons can be used with servo robots. See the chart below for compatibility or contact Star Automation for help.

|

Robot Series |

Vertical Stroke (mm) |

Range of IMM (Ton) |

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

|---|---|---|---|---|

|

400-1800 |

20-40 to 900-2500 |

100-3000 |

340-1590 |

|

|

800-1800 |

80-250 to 550-1000 |

450-2500 |

680-1130 |

|

|

1050-1700 |

80-350 to 500-1000 |

1800-2500 |

770-1130 |

|

|

2000-2500 |

1500-4000 to 2500-5000 |

3600-4000 |

1600-2000 |

|

|

100-1400 |

40-100 to 450-750 |

1000-2200 |

440-1180 |

|

|

1500-1800 |

500-1300 to 900-2500 |

2500-3000 |

1590 |

Contact our experts for more information.

Sprue Pickers for Arburg IMMs

Compact and simple to use, Star Automation’s swing-type sprue pickers are safe above all else. Our robots autonomously remove sprues from Arburg molding systems with ease. Stop unnecessary wiring and piping and make assembly more efficient with the XQ.V series. The process is further simplified with easy, quick changing of the release side. Fifteen different molds can be stored at a time.

|

Model |

Vertical Stroke |

Range of IMM |

Crosswise Stroke |

|---|---|---|---|

|

450 mm |

30-80 tons |

75 mm |

|

|

600 mm |

80-180 tons |

75 mm |

|

|

800 mm |

160-350 tons |

100 mm |

Contact our experts for more information.

Conveyor Belt Systems for Arburg IMMs

Star Automation conveyor belt systems are adjustable in height between 35 and 51 in. with a 900mm - 1300mm adjustable tilting angle. An AC120V single-phase power supply of 40 W allows for a belt speed of 10 ft per minute. Variable speed drive, indexing control, and a 32-foot power cord are equipped on every model. Additional options are available.

|

Model |

Length |

Belt Width |

Conveyable Weight (Max) |

Total Weight |

|---|---|---|---|---|

|

6’6’’ / 2000mm |

11.8” / 300mm |

110 lbs / 50 kg |

90 lbs / 41 kg |

|

|

6’6’’ / 2000mm |

15.8” / 400mm |

110 lbs / 50 kg |

97 lbs / 44 kg |

|

|

6’6’’ / 2000mm |

19.7” / 500mm |

121 lbs / 55 kg |

103 lbs / 47 kg |

|

|

6’6’’ / 2000mm |

23.6” / 600mm |

121 lbs / 55 kg |

110 lbs / 50 kg |

|

|

9’10” / 3000mm |

11.8” / 300mm |

110 lbs / 50 kg |

103 lbs / 47 kg |

|

|

9’10” / 3000mm |

15.8” / 400mm |

121 lbs / 55 kg |

112 lbs / 51 kg |

|

|

9’10” / 3000mm |

19.7” / 500mm |

121 lbs / 55 kg |

121 lbs / 55 kg |

|

|

9’10” / 3000mm |

23.6” / 600mm |

132 lbs / 60 kg |

128 lbs / 58 kg |

Contact our experts for more information.

Pallet Changer Systems for Arburg IMMs

Pallet changers help transport raw or finished plastic parts to reduce time spent on loading and unloading. Our models are numerically controlled for higher accuracy. We offer three Arburg-compatible models with varying speeds and weight capacities:

|

Model |

Container Replacement Period |

Loading Weight (Max) |

Stacking Weight (Max) |

|---|---|---|---|

|

11 seconds |

7 kg |

70 kg |

|

|

20 seconds |

15 kg |

70 kg |

|

|

4 seconds |

7 kg |

50 kg |

Contact our experts for more information.

End of Arm Tooling (E.O.A.T.) for Arburg IMMs

Eins is a division of Star Automation and produces quick change, grip, suction, and cutting EOAT features. Safety and efficiency are always top of mind. Craft tooling in-house through modular components at lower costs.

Our massive variety of E.O.A.T. parts includes