Starting as a mold maker company in Japan in 1948, MEIKI expanded its business to different parts of the world. MEIKI established in 1996 in Tijuana, Mexico, as a mold service shop incorporating injection molding, promptly meeting with the plastic parts market demands in the region, and shortly becoming a leader in the injection molding industry.

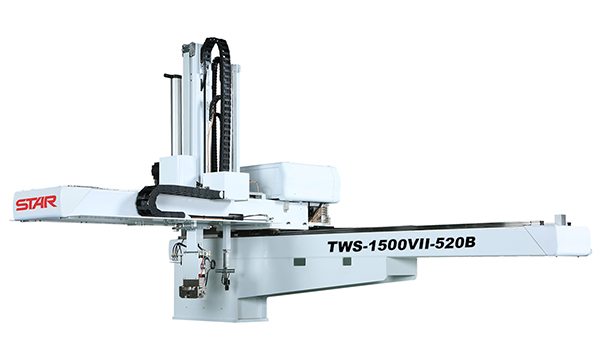

Star Automation employs the commonly used SPI 32-pin and 50-pin interfaces to ensure seamless integration with MEIKI IMMs. Our array of molding equipment includes take-out robots ranging from small to extra-large, high-speed machines specifically designed for thin-wall packaging, high-duty models, vertical machines, insert molding machines, 2-shot machines, and liquid injection molding machines. These options cater to a diverse range of needs in the molding industry.

If you have any questions, need training, maintenance, or anything in between, please reach out. We would be more than happy to assist!

Servo Robots for Meiki Injection Molding Systems

Recognized as an industry leader, Star Automation specializes in manufacturing servo motor-driven take-out robots designed specifically for Meiki IMMs. These advanced robots excel in efficiently and automatically extracting the solidified plastic product from the mold, offering a reliable solution for streamlined production processes.

|

Robot Series |

Vertical Stroke (mm) |

Range of IMM (Ton) |

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

|---|---|---|---|---|

|

400-1800 |

20-40 to 900-2500 |

100-3000 |

340-1590 |

|

|

800-1800 |

80-250 to 550-1000 |

450-2500 |

680-1130 |

|

|

1050-1700 |

80-350 to 500-1000 |

1800-2500 |

770-1130 |

|

|

2000-2500 |

1500-4000 to 2500-5000 |

3600-4000 |

1600-2000 |

|

|

100-1400 |

40-100 to 450-750 |

1000-2200 |

440-1180 |

|

|

1500-1800 |

500-1300 to 900-2500 |

2500-3000 |

1590 |

Sprue Pickers for Meiki IMMs

Star Automation provides swing-type sprue pickers that are both easy to operate and ensure safety. These pickers are compact and designed with user-friendliness in mind. With the capability to store up to 15 molds in the mold change memory, productivity is significantly enhanced. The XQ.V series simplifies assembly by eliminating unnecessary wiring and piping. Models offer different vertical stroke lengths, ranging from 450 mm to 800 mm, and switching the release side is now easier and faster for streamlined operations.

Conveyor Belt Systems for Meiki IMMs

With a height range of 35 to 51 inches and an adjustable tilting angle of 900mm to 1300mm, our models offer excellent adaptability. They are driven by a single-phase AC120V power supply, consuming 40 W and achieving a belt speed of 10 feet per minute. Each model is equipped with a variable speed drive, indexing control, and a generous 32-foot power cord. Moreover, a variety of additional options are available for further customization as needed. Additional options are available.

|

Model |

Length |

Belt Width |

Conveyable Weight (Max) |

Total Weight |

|---|---|---|---|---|

|

6’6’’ / 2000mm |

11.8” / 300mm |

110 lbs / 50 kg |

90 lbs / 41 kg |

|

|

6’6’’ / 2000mm |

15.8” / 400mm |

110 lbs / 50 kg |

97 lbs / 44 kg |

|

|

6’6’’ / 2000mm |

19.7” / 500mm |

121 lbs / 55 kg |

103 lbs / 47 kg |

|

|

6’6’’ / 2000mm |

23.6” / 600mm |

121 lbs / 55 kg |

110 lbs / 50 kg |

|

|

9’10” / 3000mm |

11.8” / 300mm |

110 lbs / 50 kg |

103 lbs / 47 kg |

|

|

9’10” / 3000mm |

15.8” / 400mm |

121 lbs / 55 kg |

112 lbs / 51 kg |

|

|

9’10” / 3000mm |

19.7” / 500mm |

121 lbs / 55 kg |

121 lbs / 55 kg |

|

|

9’10” / 3000mm |

23.6” / 600mm |

132 lbs / 60 kg |

128 lbs / 58 kg |

Pallet Changer Systems for Meiki IMMs

Revolutionize your material handling processes with pallet changers, streamlining the transportation of raw or finished plastic parts and significantly reducing loading and unloading time. Our models are equipped with advanced numerical control technology, guaranteeing exceptional accuracy. Explore our range of three Meiki-compatible models, each engineered with varying speeds and weight capacities to accommodate diverse operational needs.

|

Model |

Container Replacement Period |

Loading Weight (Max) |

Stacking Weight (Max) |

|---|---|---|---|

|

11 seconds |

7 kg |

70 kg |

|

|

20 seconds |

15 kg |

70 kg |

|

|

4 seconds |

7 kg |

50 kg |

End of Arm Tooling (E.O.A.T.) for Meiki IMMs

We offer a wide array of E.O.A.T. attachments for Meiki IMMs for a variety of applications. Whether you’re looking for cutting tools, gripping or suction components, Star Automation is here to help.

Our massive variety of E.O.A.T. parts includes:

For more information or a free quote on automation robots for Meiki brand IMMs, contact Star Automation today.