Sumitomo Heavy Industries specializes in “zero-molding” technology, which gets as close to zero defects, losses, and faults as possible. They offer a variety of injection molding machines, small, horizontal, large, vertical, double-shot, and special-purpose machines.

Our servo robots, sprue pickers, conveyor belts, pallet changers, and end-of-arm tooling are compatible with Sumitomo zero-molding injection molding machines through 32-pin and 50-pin standardized interfacing. Older presses can be connected via direct wiring through a terminal strip interface.

The experts at Star Automation will work with you every step of the way. We’ll help with installation, training, maintenance, and repairs.

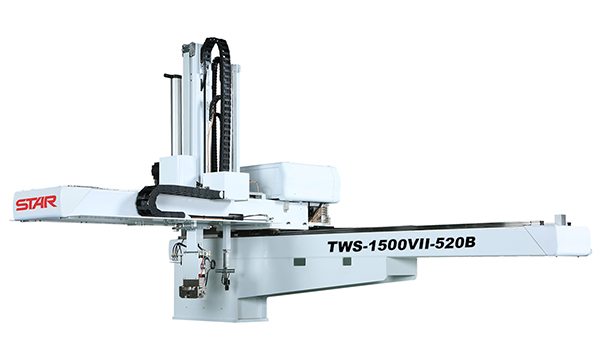

Servo Robots for Sumitomo Injection Molding Systems

We have 13 options of servo robots for Sumitomo injection molding machines. Our autonomous robot arms are perfect for removing plastic products once they’ve hardened in the mold. We have options that range between 400-2500 mm of vertical stroke capacity, with a weight range between 20 and 5000 tons.

|

Robot Series |

Vertical Stroke (mm) |

Range of IMM (Ton) |

Traverse Stroke (mm) |

Crosswise Stroke (mm) |

|---|---|---|---|---|

|

400-1800 |

20-40 to 900-2500 |

100-3000 |

340-1590 |

|

|

800-1800 |

80-250 to 550-1000 |

450-2500 |

680-1130 |

|

|

1050-1700 |

80-350 to 500-1000 |

1800-2500 |

770-1130 |

|

|

2000-2500 |

1500-4000 to 2500-5000 |

3600-4000 |

1600-2000 |

|

|

100-1400 |

40-100 to 450-750 |

1000-2200 |

440-1180 |

|

|

1500-1800 |

500-1300 to 900-2500 |

2500-3000 |

1590 |

Sprue Pickers for Sumitomo IMMs

Our sprue pickers are compatible with all Sumitomo makes and models and work to discard excess plastic from the mold. This plastic is then recycled for future use. We offer three models, depending on your automation system’s specific needs.

Conveyor Belt Systems for Sumitomo IMMs

Moving products from point A to point B has never been easier. A conveyor belt system is a fantastic addition to any Sumitomo IMM, as it allows for reduced down time and increased productivity in the long run. We offer two basic sizes, the 6’6” model and the 9’10” model, with varying belt widths and weight capacities.

All of our models have an adjustable height between 35 and 51 in. with a 900mm - 1300mm adjustable tilting angle. They have an AC120V single-phase power supply of 40 W that allows for a belt speed of 10 ft per minute. Each model includes a variable speed drive, indexing control, and a 32-foot power cord. Additional options are available.

|

Model |

Length |

Belt Width |

Conveyable Weight (Max) |

Total Weight |

|---|---|---|---|---|

|

6’6’’ / 2000mm |

11.8” / 300mm |

110 lbs / 50 kg |

90 lbs / 41 kg |

|

|

6’6’’ / 2000mm |

15.8” / 400mm |

110 lbs / 50 kg |

97 lbs / 44 kg |

|

|

6’6’’ / 2000mm |

19.7” / 500mm |

121 lbs / 55 kg |

103 lbs / 47 kg |

|

|

6’6’’ / 2000mm |

23.6” / 600mm |

121 lbs / 55 kg |

110 lbs / 50 kg |

|

|

9’10” / 3000mm |

11.8” / 300mm |

110 lbs / 50 kg |

103 lbs / 47 kg |

|

|

9’10” / 3000mm |

15.8” / 400mm |

121 lbs / 55 kg |

112 lbs / 51 kg |

|

|

9’10” / 3000mm |

19.7” / 500mm |

121 lbs / 55 kg |

121 lbs / 55 kg |

|

|

9’10” / 3000mm |

23.6” / 600mm |

132 lbs / 60 kg |

128 lbs / 58 kg |

Pallet Changer Systems for Sumitomo IMMs

Keep your plastic components separated and organized with a pallet changer system for your Sumitomo injection molding machine. Our models will help you make more economical use of your floor space. We offer three models, depending on your automation system’s needs.

|

Model |

Container Replacement Period |

Loading Weight (Max) |

Stacking Weight (Max) |

|---|---|---|---|

|

11 seconds |

7 kg |

70 kg |

|

|

20 seconds |

15 kg |

70 kg |

|

|

4 seconds |

7 kg |

50 kg |

End of Arm Tooling (E.O.A.T.) for Sumitomo IMMs

We offer a wide selection of end-of-arm tooling options for your Sumitomo IMM. Grab, cut, grip or suction your components with a specially fitted E.O.A.T. from Star Automation.

For questions on which part is right for your job, connect with one of our experts today.

For more information or a free quote on automation robots for Sumitomo brand IMMs, contact Star Automation today.